Automatic gearboxes

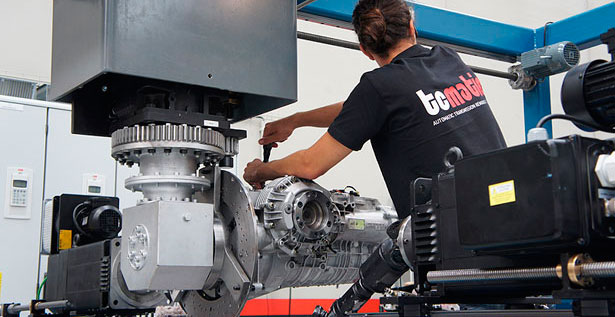

All units repaired and remanufactured at TCMATIC are subjected to stringent quality controls in a testbed that integrates test protocols according to the specifications of the original manufacturers.

All units repaired and remanufactured at TCMATIC are subject to stringent quality controls in a testbed that integrates test protocols according to the specifications of the original manufacturers and our departments of product quality and control.

Our repair and remanufacturing process begins on the assembly lines where specialized technicians dismantle the boxes on individual workbenches. After a first washing in industrial equipment units, our quality department analyses and verifies all the pieces and components of the set, one by one.

The torque converters are transferred to the converter reconstruction section, where they are subjected to a special prefabrication process. The valve bodies are also transferred to their specific section of verification, repair and control. On the assembly lines, the technicians reconstruct the transmissions, replacing all the pieces marked by the quality department. 100% of the spare parts that are used for the reconstruction are original spare parts from the manufacturer.

Once the reconstruction and assembly of all the components has been completed, the set is transported to the final product control section, where it undergoes stringent quality tests in a testbed. Each brand has its own test protocol based on the manufacturer’s original specifications.

We have our own control software, as well as different commercial platforms that allow us to compare each trial, and so certify our guarantee.